Before we begin, let me say a few things about this website. I do not go out of my way to publicize the URL, other than a few random posts on electronics forums over the years. So if you got here, you probably are very good at hunting down test equipment information. This site was started many years ago as a simple portable way for me to keep track of my test equipment and the repairs I made. I wrote it in an irreverent style because I was the only one who was ever going to see it. But as I gave the address to a few friends and colleagues, it became clear that my audience was larger than just one, and they seemed to enjoy my commentary on the equipment. Now there are probably several hundred people that occasionally visit this website and I am sure that some do not like my style. Sorry.

WHAT'S NEW? LATEST ADDITIONS TO THIS WEBSITE:

Sencore FC45 (March, 2024)

HP 1740A (March, 2024)

Pacific Measurements 1034A (February, 2024)

HP 6205C (January, 2024)

Adret 2230A (December, 2023)

Racal 9083N (November, 2023)

Wavetek 154 (see the "It's Dead, Jim" section) (November, 2023)

HP 8013B (October, 2023)

Hitachi VC-7104 (September, 2023)

Note: New/modified repair notes are not individually listed as latest additions since they occur too frequently to keep track of them all!

---------------------------------------------------------

This is my (ever changing) collection of old test equipment. Most of the collection dates from what I consider to be the peak period in repairable semiconductor based test equipment, 1970 to 1990. Manufacturers like HP and Tektronix usually prepared exquisite service manuals, something unheard of today. On the other hand, they sometimes used custom ICs that are only very rarely now available. But compared to most equipment made after 1990, for which "repair" means "board replacement," these earlier pieces offer a fun and usually solvable challenge. Almost every piece in the collection that I received broken has been successfully repaired and restored to original specifications.

There are currently 467 pieces in my collection. But that's likely to change tomorrow. Maybe even in the time it takes you to read this page. HP equipment makes up the largest subset by far (> 150 pieces). Other major vendors include Tektronix, Fluke and Wavetek. Each major manufacturer had their own ways of doing things which often times were strikingly unique. But for my money (which it is), I am an HP connoisseur and simply can't bear to let one of their pieces perish if the price is right.

Virtually all of the pieces were bought on eBay. My constraint is usually to pay no more than 2% of the latest catalog MSRP. Sticking to this constraint means that the items are usually broken. But that's the whole point, isn't it? The pieces that were not bought were usually given to me by friends and relatives. A couple of pieces were literally picked out of the garbage can.

Those pieces that were received in some state of disrepair (something more than simple dirty switches/pots or misalignments) and were repaired by me have some brief repair notes in blue below their descriptions. Well, they started out as brief. As I collected more equipment, the repair descriptions became more and more verbose and described much of the repair journey. At the bottom of this page are some general comments on repair.

While the descriptions and repair notes are accurate, each reflects my state of mind and state of equipment at the time I wrote it. So often times I make comments, such as "the best scope I own," which may no longer be true. I haven't gone back and reworked various descriptions. Life is too short.

I've said nothing about operation and service manuals. For the most part, these are necessary in order to repair things. Not mandatory, and I've certainly fixed a lot of stuff without them mainly by visual inspection. To paraphrase Yogi Berra, "You can see a lot by looking." But finding manuals is almost as much fun as finding the equipment. Some can be had for free, some can be had for a few bucks, and some can be had from retail manual dealers. It is not at all uncommon to spend more for the manual than I did for the piece of equipment. Such is life. The manual status is provided at the end of each unit's description:

(OM) - Original hard copy manual purchased from a dealer

(PDF) - PDF file obtained for free

($CD) - Soft copy manual purchased and delivered via CD or download

(---) - Don't have

Almost all the (PDF) and ($CD) manuals were printed out locally. Several of the manuals I purchased were later found online for free. What, you think life is fair?

WHAT'S NEW? LATEST ADDITIONS TO THIS WEBSITE:

Sencore FC45 (March, 2024)

HP 1740A (March, 2024)

Pacific Measurements 1034A (February, 2024)

HP 6205C (January, 2024)

Adret 2230A (December, 2023)

Racal 9083N (November, 2023)

Wavetek 154 (see the "It's Dead, Jim" section) (November, 2023)

HP 8013B (October, 2023)

Hitachi VC-7104 (September, 2023)

Note: New/modified repair notes are not individually listed as latest additions since they occur too frequently to keep track of them all!

---------------------------------------------------------

This is my (ever changing) collection of old test equipment. Most of the collection dates from what I consider to be the peak period in repairable semiconductor based test equipment, 1970 to 1990. Manufacturers like HP and Tektronix usually prepared exquisite service manuals, something unheard of today. On the other hand, they sometimes used custom ICs that are only very rarely now available. But compared to most equipment made after 1990, for which "repair" means "board replacement," these earlier pieces offer a fun and usually solvable challenge. Almost every piece in the collection that I received broken has been successfully repaired and restored to original specifications.

There are currently 467 pieces in my collection. But that's likely to change tomorrow. Maybe even in the time it takes you to read this page. HP equipment makes up the largest subset by far (> 150 pieces). Other major vendors include Tektronix, Fluke and Wavetek. Each major manufacturer had their own ways of doing things which often times were strikingly unique. But for my money (which it is), I am an HP connoisseur and simply can't bear to let one of their pieces perish if the price is right.

Virtually all of the pieces were bought on eBay. My constraint is usually to pay no more than 2% of the latest catalog MSRP. Sticking to this constraint means that the items are usually broken. But that's the whole point, isn't it? The pieces that were not bought were usually given to me by friends and relatives. A couple of pieces were literally picked out of the garbage can.

Those pieces that were received in some state of disrepair (something more than simple dirty switches/pots or misalignments) and were repaired by me have some brief repair notes in blue below their descriptions. Well, they started out as brief. As I collected more equipment, the repair descriptions became more and more verbose and described much of the repair journey. At the bottom of this page are some general comments on repair.

While the descriptions and repair notes are accurate, each reflects my state of mind and state of equipment at the time I wrote it. So often times I make comments, such as "the best scope I own," which may no longer be true. I haven't gone back and reworked various descriptions. Life is too short.

I've said nothing about operation and service manuals. For the most part, these are necessary in order to repair things. Not mandatory, and I've certainly fixed a lot of stuff without them mainly by visual inspection. To paraphrase Yogi Berra, "You can see a lot by looking." But finding manuals is almost as much fun as finding the equipment. Some can be had for free, some can be had for a few bucks, and some can be had from retail manual dealers. It is not at all uncommon to spend more for the manual than I did for the piece of equipment. Such is life. The manual status is provided at the end of each unit's description:

(OM) - Original hard copy manual purchased from a dealer

(PDF) - PDF file obtained for free

($CD) - Soft copy manual purchased and delivered via CD or download

(---) - Don't have

Almost all the (PDF) and ($CD) manuals were printed out locally. Several of the manuals I purchased were later found online for free. What, you think life is fair?

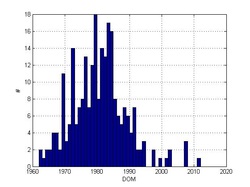

Here is a histogram of the manufacture dates of the pieces listed on this page. Most of these dates were gleaned from the date codes of the ICs inside. One often cannot rely upon date codes embedded in serial numbers (sometimes that number refers to the design rev date, not the manufacture date).

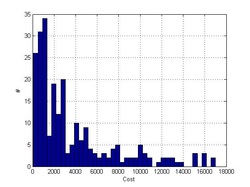

And here is a histogram of MSRPs up to about $20,000. I have a few items more expensive, but they weren't included in this plot. Using the latest catalog price is somewhat iffy since some manufacturers, in particular HP, often skyrocketed their prices right before they discontinued an item. Whether this cost increase was due to the difficulty in obtaining parts, or whether it was used as an inducement to buy the replacement model, isn't exactly clear to me.

Finally, everyone is entitled to their own opinion. But on this web page, everyone is entitled to MY own opinion! So I have given each piece in the current collection a letter grade loosely based upon the following criteria:

I would have also included my cost in the above list, but I haven't been keeping records. If I had to, I would guess that my average cost is about $50 per piece. Just a guess.

Also scattered about are several "bonus rants." These pontifications usually occur when a piece frustrates me to the point of wanting to toss it across my basement or when a manufacturer consistently seems to be doing something dumb. Earning a rant does not necessarily imply a bad grade, however.

- Build quality (mechanical, electrical and ease of repair)

- Performance and/or specifications

- Ease of use

- Uniqueness (does every manufacturer make one or is there some functionality unique to this piece?)

- Innovation (at the time of manufacture, did the piece incorporate major design innovations?)

I would have also included my cost in the above list, but I haven't been keeping records. If I had to, I would guess that my average cost is about $50 per piece. Just a guess.

Also scattered about are several "bonus rants." These pontifications usually occur when a piece frustrates me to the point of wanting to toss it across my basement or when a manufacturer consistently seems to be doing something dumb. Earning a rant does not necessarily imply a bad grade, however.

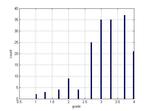

Here is a histogram of the grades using the standard 0-4 GPA mapping. Like the current situation in higher education, it reveals some grade inflation. The average of the grades is 3.14 - a solid "B." This chart was made at about piece #170. I haven't bothered to update it since and I doubt that the overall average would change much anyway.

If you feel that you disagree with a piece's letter grade, I suggest you remember what happened to you when you went up to the professor after class and asked that your grade be changed. Maybe you never did that, but I once went up to the professor in college after receiving a 99 on a math exam. I looked all through the exam paper for the stupid algebra mistake I must have made to cost me one point, but there wasn't a red mark anywhere to be found. So I asked the professor why I got a 99 instead of 100. His reply was simply, "I don't give 100s."

I know what you are thinking - where does he put all this stuff? Well, believe it or not, it all fits in a small corner of my basement. But that means I basically have to stack stuff from floor to ceiling. Most of the stuff I use frequently is plugged into AC and near my (small) work area. The outlying pieces generally are not plugged in, but things are arranged so I can easily get to the back to plug in power cords.

If you feel that you disagree with a piece's letter grade, I suggest you remember what happened to you when you went up to the professor after class and asked that your grade be changed. Maybe you never did that, but I once went up to the professor in college after receiving a 99 on a math exam. I looked all through the exam paper for the stupid algebra mistake I must have made to cost me one point, but there wasn't a red mark anywhere to be found. So I asked the professor why I got a 99 instead of 100. His reply was simply, "I don't give 100s."

I know what you are thinking - where does he put all this stuff? Well, believe it or not, it all fits in a small corner of my basement. But that means I basically have to stack stuff from floor to ceiling. Most of the stuff I use frequently is plugged into AC and near my (small) work area. The outlying pieces generally are not plugged in, but things are arranged so I can easily get to the back to plug in power cords.

AND NOW, HERE IS THE COLLECTION!

Instructions: Scroll Down, Click on Pictures to Expand.

Like the Energizer Bunny, just keep going and going...

A : AC/DC, Adret, Advantest, Associated Research, Atten, Audiolab, AUL

AC DC EL750B: Dynamic DC electronic load. Will handle 750 watts (up to 50V and up to 150A). Can set two levels for 120 Hz or 1 kHz dynamic switching. Has I and R modes but no V mode like the more expensive units. My only complaint is that the smallest range is 10A, so adjusting the load from very small currents (e.g., batteries) is hard. This unit runs very cool - I've dumped 100 watts into it for hours and could feel no heat anywhere. (OM) Grade: B+

This piece came to me with a defective P/S which was due to an open AC transformer - a very rare situation indeed. If that wasn't enough, three of the sixteen load transistors were blown (one had a hole burned through the TO-3 case). And the voltmeter didn't work either. I gutted the P/S and built a new one, replaced all sixteen load transistors, exchanged the old voltmeter mechanism with a new one (keeping the existing meter face). I also replaced the load adjust pot with a three turn pot for finer control.

This piece came to me with a defective P/S which was due to an open AC transformer - a very rare situation indeed. If that wasn't enough, three of the sixteen load transistors were blown (one had a hole burned through the TO-3 case). And the voltmeter didn't work either. I gutted the P/S and built a new one, replaced all sixteen load transistors, exchanged the old voltmeter mechanism with a new one (keeping the existing meter face). I also replaced the load adjust pot with a three turn pot for finer control.

Adret 2230A: This is a curious 1 MHz synthesizer with 1 Hz resolution and amplitudes from about +20 dBm to -70 dBm. You will notice that the synthesizer has thumbwheel switches for frequency (and amplitude) and also a big knob underneath. The synthesizer can be put in "generate" mode and the output frequency is controlled by the knob (from 0 to 1 MHz). When the frequency dialed in from the knob agrees with whatever is set on the thumbwheel switches, the "error" LEDs adjacent to the knob slowly blink (otherwise a solid LED shows whether you are high or low). The 2230A can also be put in sweep mode controllable by an external DC voltage. Otherwise, the basic controls are a bid odd as you can tell from the picture and I won't elaborate further here. I only have one other Adret piece (CS-201SB) and I have to say that at least in the late 1970's, early 1980's, Adret was producing equipment just as good as any of the (worldwide) test equipment manufacturers. (OM) Grade: A-

This piece was bought for $40 shipped including the paper op/service manual. That's pretty good as shipping alone had to cost the seller at least $20. When received (in advertised condition unknown), it powered on but produced no output. A few minutes later, I heard a pop and the piece went dead, drawing no power from the AC line. The main fuse had blown and the piece was wafting the unmistaken smell of a burnt tantalum capacitor. Opening up the piece, I saw one tantalum that had half severely discolored black. As I went to remove and replace it, I noticed that it wasn't that capacitor that burned. Nope, it was the adjacent tantalum that exploded and was now completely missing. So two new capacitors were installed and the piece sprang to life. Everything seemed OK, but then I noticed that, particularly when using the 100 kHz digit switch, the output frequency would be way off. Moving the switch to a different frequency and then quickly returning to the same selection produced the right output. Since the main operating circuit involves a VCO/PLL, it seemed to me like a somewhat familiar case of the VCO being slightly off frequency and not in the capture range of the PLL. A slight tweak of an adjustable transformer adjacent to the VCO circuitry quickly fixed the problem. The only other thing wrong was that the back panel 1 MHz output reference signal was absent. This was traced to an open secondary of a transformer. The transformer in the parts list was marked "38/6, 33 uH," and I interpreted that as 38:6 turns ratio and a 33 uH primary. I found something close from Coilcraft for $3 and installed it a few inches from where it should have been (it was too big to fit in the original spot). Problem solved. What was even stranger was that the faulty transformer tested in-circuit short on the primary (as expected) and open on the secondary. But when I pulled it out, the primary also tested open. There was a solder-blob short between two traces about 1/4 inch from the primary. The solder looked original to the unit, so there is no way that the 1 MHz would appear on the output even if the transformer was good. I guess it was an original manufacturing error. Finally, the spec says -55 dBc for harmonics, but I'm only getting -50 dBc. There is no adjustment information in the manual, so I'm not about to start adjusting various transformers to see if I can tweak it.

This piece was bought for $40 shipped including the paper op/service manual. That's pretty good as shipping alone had to cost the seller at least $20. When received (in advertised condition unknown), it powered on but produced no output. A few minutes later, I heard a pop and the piece went dead, drawing no power from the AC line. The main fuse had blown and the piece was wafting the unmistaken smell of a burnt tantalum capacitor. Opening up the piece, I saw one tantalum that had half severely discolored black. As I went to remove and replace it, I noticed that it wasn't that capacitor that burned. Nope, it was the adjacent tantalum that exploded and was now completely missing. So two new capacitors were installed and the piece sprang to life. Everything seemed OK, but then I noticed that, particularly when using the 100 kHz digit switch, the output frequency would be way off. Moving the switch to a different frequency and then quickly returning to the same selection produced the right output. Since the main operating circuit involves a VCO/PLL, it seemed to me like a somewhat familiar case of the VCO being slightly off frequency and not in the capture range of the PLL. A slight tweak of an adjustable transformer adjacent to the VCO circuitry quickly fixed the problem. The only other thing wrong was that the back panel 1 MHz output reference signal was absent. This was traced to an open secondary of a transformer. The transformer in the parts list was marked "38/6, 33 uH," and I interpreted that as 38:6 turns ratio and a 33 uH primary. I found something close from Coilcraft for $3 and installed it a few inches from where it should have been (it was too big to fit in the original spot). Problem solved. What was even stranger was that the faulty transformer tested in-circuit short on the primary (as expected) and open on the secondary. But when I pulled it out, the primary also tested open. There was a solder-blob short between two traces about 1/4 inch from the primary. The solder looked original to the unit, so there is no way that the 1 MHz would appear on the output even if the transformer was good. I guess it was an original manufacturing error. Finally, the spec says -55 dBc for harmonics, but I'm only getting -50 dBc. There is no adjustment information in the manual, so I'm not about to start adjusting various transformers to see if I can tweak it.

Adret CS-201SB: 2 MHz synthesizer. This was a replacement piece for the broken Adret 201 described in detail in the "It's Dead, Jim" section near the bottom of this web page. The "SB" model omits the AM/FM modulation capability, but does have more precise control over the amplitude. It also works with the Adret 211 external control box also described below. I bought this with the idea of using the parts to fix the original 201. But it works fine right out of the box, so we will stay with this one. While the original one had 1966 date codes on some of the parts, this newer SB version has 1986 date codes. Adret also cleaned up the layout quite a bit. From what I can ascertain, Adret was well known for its synthesizers 50 years ago, and I must confess that their early pieces were way ahead of HP and Tektronix at that time. (PDF) Grade: A-

Advantest R6871E-DC: 7-1/2 precision DMM from the Japanese. This is a real sleeper. I would put it on par with any of my top HP, Fluke or Datron DMMs. Advantest made a full 6871E model (DCV, ACV, DCI, ACI, ohms) and the more modest 6871E-DC model which only does DCV and ohms. Unfortunately, mine is the latter, but if I ever see a good price on the full model, I won't hesitate to buy it. The best-range 24 hour DCV and ohms specs are about 0.0012% and 0.002% respectively at 24 hours, rising to 0.0037% and 0.006% at 180 days. Calibration is via software controlled by the front panel. The user gets much more control over sampling interval, number of power-line cycles and averaging than is usually found in DMMs. There is also a small set of math and statistic functions as well as auto-zero and auto-cal functions. The only downside to this meter is that it is HUGE - 12" x 6" x 18". Whereas a lot of non-rackmountable DMMs, such as the Advantest TR6845 and TR6857 models shown below, could be considered portable and shuffled around the lab bench, the R6871E is much too large for that. All in all, a fantastic buy at $50. (PDF) Grade: A.

I took somewhat of a gamble on this because there is no service manual available (and maybe no service manual in existence). The seller said, "When unit powers on, no lights on display." But the back panel showed the thing set for 220 VAC, so no wonder. The operator's manual was obtainable on-line and said that the AC line voltage is set at the factory at the time of purchase (separate options for 100, 120, 200, 220 or 240 VAC). I gambled that I could reset the line voltage to 120 VAC as my other two Advantest DMMs had clearly labeled jumpers for that on the circuit board. But when I opened up the R6871E-DC, all I found were six wires going to a six-pin terminal strip with a jumper between pins 2 and 4. I took a guess that that was the two primaries run in series, so I jumpered 1-4 and 2-5 to (hopefully) put the primaries in parallel. I have no clue what pins 3 and 6 are for. The piece sprang to life, passed all tests and calibrated nicely. I've since found a picture of the terminal strip from an eevblog user who posted teardown pictures and his 120 VAC unit was jumpered the way I guessed.

I took somewhat of a gamble on this because there is no service manual available (and maybe no service manual in existence). The seller said, "When unit powers on, no lights on display." But the back panel showed the thing set for 220 VAC, so no wonder. The operator's manual was obtainable on-line and said that the AC line voltage is set at the factory at the time of purchase (separate options for 100, 120, 200, 220 or 240 VAC). I gambled that I could reset the line voltage to 120 VAC as my other two Advantest DMMs had clearly labeled jumpers for that on the circuit board. But when I opened up the R6871E-DC, all I found were six wires going to a six-pin terminal strip with a jumper between pins 2 and 4. I took a guess that that was the two primaries run in series, so I jumpered 1-4 and 2-5 to (hopefully) put the primaries in parallel. I have no clue what pins 3 and 6 are for. The piece sprang to life, passed all tests and calibrated nicely. I've since found a picture of the terminal strip from an eevblog user who posted teardown pictures and his 120 VAC unit was jumpered the way I guessed.

Advantest TR6845: At least this unit has a continuity tester. Very easy to use, pretty accurate (although not as good as the HP units). One of two. The build quality on the TR6845 (and the TR6847 below) is very good. Don't let the cheap plastic look fool you, Advantest knew what they were doing. (---) Grade: B

Advantest TR6847: A cute DMM that for some reason does not have a continuity tester (actually it does by combining the ohms function and the "beep" function). Takes readings ten times faster than the TR6845 and is twice as accurate. Presumably Advantest made a slew of DMMs at various price points. (---) Grade: B

Associated Research 2100A: High resistance meter. This is a somewhat odd megohmmeter that measures in four ranges, 200M, 500M, 1000M and 2000M, using a maximum of 50 uA at 100, 250, 500 and 1000 VDC respectively. It also has a 20K range (5 volt source) and a 600 VAC range for some strange reason. The unit has a tray for 8 D-cell batteries and a jack for a 12 VDC external supply. It has a nice sturdy metal hinged case and came complete with three test leads, the operation manual and original paperwork. This thing is basically a step-up switching power supply and a bunch of range resistors, but has far more componentry than I would have expected (pwm modulator IC, quad comparator, 555 timer, etc.). Kind of limited, especially when you compare it to my HP 4329A High Resistance Meter, but for ten bucks, who cares? (OM) Grade: B

This piece was received in "condition unknown" and after I installed batteries, the meter didn't move at all on any setting. And that was because the meter glass had worked free and was pressing against the faceplate trapping the needle. After I glued the glass back, the piece gave approximately the correct readings. Full scale (zero ohms) on all ranges was a bit low, but there were five 10-turn pots inside that corrected that on the five resistance ranges. There are also three other pots that must adjust something, but I don't know what. When I hooked the test leads up to my Fluke 8502A DMM, I only measured 83.6, 167, 250 and 334 VDC coming out of the unit on the 100, 250, 500 and 1000 V ranges. This had me perplexed for a while. Seems as though the 2100A will throttle the output voltage and current back from the maximum value if the resistance under test is low. And since the Fluke 8502A DMM only has a 10 meg input impedance on the 1000 VDC scale, I guess that was what happened. In order to verify that the 2100A is capable of outputting 1000 VDC, I cut a 5/8" piece of cardboard Q-tip which I then measured to be about 1 gigaohm with my HP 4329A High Resistance Meter. Put that in series with the 8502A DMM which gave me about a 100:1 voltage divider. I then measured the divided voltage and it was about 10 volts which proved the 2100A was outputting the maximum voltage.

This piece was received in "condition unknown" and after I installed batteries, the meter didn't move at all on any setting. And that was because the meter glass had worked free and was pressing against the faceplate trapping the needle. After I glued the glass back, the piece gave approximately the correct readings. Full scale (zero ohms) on all ranges was a bit low, but there were five 10-turn pots inside that corrected that on the five resistance ranges. There are also three other pots that must adjust something, but I don't know what. When I hooked the test leads up to my Fluke 8502A DMM, I only measured 83.6, 167, 250 and 334 VDC coming out of the unit on the 100, 250, 500 and 1000 V ranges. This had me perplexed for a while. Seems as though the 2100A will throttle the output voltage and current back from the maximum value if the resistance under test is low. And since the Fluke 8502A DMM only has a 10 meg input impedance on the 1000 VDC scale, I guess that was what happened. In order to verify that the 2100A is capable of outputting 1000 VDC, I cut a 5/8" piece of cardboard Q-tip which I then measured to be about 1 gigaohm with my HP 4329A High Resistance Meter. Put that in series with the 8502A DMM which gave me about a 100:1 voltage divider. I then measured the divided voltage and it was about 10 volts which proved the 2100A was outputting the maximum voltage.

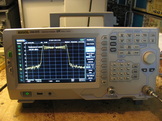

Atten 5011: DC-1.1 GHz spectrum analyzer. Cheap Chinese knockoff, but useful for a quick survey or to check harmonics of signal generators and the like. Very limited selection of two resolution bandwidths plus a drift of 100 kHz in one hour. This really is a poor man's spectrum analyzer. It's one of the very few pieces that I bought new and I've been disappointed with it ever since. Typical Chinese construction using low grade parts, poor board layouts, poor mechanicals, etc. Those viewing this page may note that there are very few spectrum analyzers listed. For some inexplicable reason, the eBay prices on used spectrum analyzers are proportionally way out of line compared to just about any other class of equipment. (OM) Grade: C-

Postscript: Not that I have any use for this piece given my other spectrum analyzers, but I recently turned it on after a few years of dormancy just to see if it still worked. It didn't. In fact, the CRT was dark (although the filament was glowing) and the display and controls were frozen at the upper frequency limit. I gave it the visual once-over, but everything looked fine. By some quirk, the service manual for the re-branded Hameg HM5011 was on the web and if it weren't for that, I would have given up. The immediate problem was that the 12V line was shorted. This serves as the reference for -12V and for the voltages that are developed to supply the CRT, so no wonder everything was hosed. I pulled the P/S output line and the short was confined to the P/S. The pass transistor output has two capacitors hung off the output and I was sure it had to be one of those, since nothing else had a clear path (without a resistor) to ground. But it turned out to be the thermal insulator for the pass transistor that had failed, shorting the case to ground. After that was fixed, all the controls/displays went back to normal, except that the CRT was still dark. The -2000V going into the CRT board from the P/S was fine, so I pulled the CRT board and took a look. There was a 4N35 photo-transistor in a socket and when I pulled that and put it on the component transistor, the diode was OK but the transistor was toast. I managed to find an MCT2E in the junkbox and threw that in. Whoopee, the CRT came up just fine. There is also an LED hung off the base of the photo-transistor which is unlit and my guess is that opened up as well when the photo-transistor blew. I'll test/replace it one of these days. Until then, back on the pile the 5011 goes for a few more years.

Postscript: Not that I have any use for this piece given my other spectrum analyzers, but I recently turned it on after a few years of dormancy just to see if it still worked. It didn't. In fact, the CRT was dark (although the filament was glowing) and the display and controls were frozen at the upper frequency limit. I gave it the visual once-over, but everything looked fine. By some quirk, the service manual for the re-branded Hameg HM5011 was on the web and if it weren't for that, I would have given up. The immediate problem was that the 12V line was shorted. This serves as the reference for -12V and for the voltages that are developed to supply the CRT, so no wonder everything was hosed. I pulled the P/S output line and the short was confined to the P/S. The pass transistor output has two capacitors hung off the output and I was sure it had to be one of those, since nothing else had a clear path (without a resistor) to ground. But it turned out to be the thermal insulator for the pass transistor that had failed, shorting the case to ground. After that was fixed, all the controls/displays went back to normal, except that the CRT was still dark. The -2000V going into the CRT board from the P/S was fine, so I pulled the CRT board and took a look. There was a 4N35 photo-transistor in a socket and when I pulled that and put it on the component transistor, the diode was OK but the transistor was toast. I managed to find an MCT2E in the junkbox and threw that in. Whoopee, the CRT came up just fine. There is also an LED hung off the base of the photo-transistor which is unlit and my guess is that opened up as well when the photo-transistor blew. I'll test/replace it one of these days. Until then, back on the pile the 5011 goes for a few more years.

Audiolab TD-1B: "The Audiolab TD-1B Professional Tape Degausser is designed for the demanding broadcast industry," so sayeth the datasheet. I guess maybe in 1970 that was true. I bought this during my tape recorder "phase", e.g., the Racal 14DS and HP 3964A. Take an 8 lb 115V/8A transformer, throw it in a pretty Bakelite box with a switch and voila. Does 1500 Gauss. If you know what that means, you've really got too much time on your hands. (--) Grade: B-

AUL Instruments ME-30F/U: AC Voltmeter. This one is somewhat of a mystery. There is a label on the bottom that says ME-30F/U, but it looks like someone cut this out from somewhere (it is not quite rectangular) and taped it the cabinet. Information on the ME-30F/U is nowhere to be found, but the front and rear panels look suspiciously like an HP 400E AC voltmeter. In fact, upon closer examination, the circuit board is 99% identical to the HP 400E, even down to the component numbering. There are two extra adjustment pots, the meter and case are obviously different, the P/S is adjusted nominally to 22 VDC rather than the 26 VDC in the HP 400E, and the internal bias is 8 VDC instead of 10 VDC, but otherwise it is an HP 400E. So I have no idea what is going on - why did the military commission this piece instead of simply buying an HP 400E? Spec-wise, it does frequencies up to 10 MHz and has ranges from 1 mV to 300 V full scale. (---) Grade: B+

The only damage when received was the AC power jack, the old-style HP type, which was all burnt up and one of the pins was missing. The jack was replaced with the more modern type. I tweaked the adjustment pots, but the thing already was close to perfect.

The only damage when received was the AC power jack, the old-style HP type, which was all burnt up and one of the pins was missing. The jack was replaced with the more modern type. I tweaked the adjustment pots, but the thing already was close to perfect.

AUL Instruments ME-202B: Old school differential voltmeter. This one is about 1 mV off. This piece was one of those <$10 junkers that looked like fun. Of course, any decent digital voltmeter (HP 3455, 3456, 3490, 3468) will outperform the ME-202, but I guess nulling voltmeters had their place years before. (PDF) Grade: C-

This was so jostled in shipping that the boards inside had broken free of their standoffs. Many wires had also broken clean off. Without a schematic, I took a guess and glued all the boards down and rewired everything. Seems to work just fine now.

Postscript: I hadn't used this piece in so many years that when I finally did, it was out of calibration. Attempting to recalibrate revealed a problem in one of the ten-turn adjustment pots, so it was replaced.

This was so jostled in shipping that the boards inside had broken free of their standoffs. Many wires had also broken clean off. Without a schematic, I took a guess and glued all the boards down and rewired everything. Seems to work just fine now.

Postscript: I hadn't used this piece in so many years that when I finally did, it was out of calibration. Attempting to recalibrate revealed a problem in one of the ten-turn adjustment pots, so it was replaced.

B : Ballantine, BBC, Beco, Biddle Gray, Biomation, BK Precision, Boonton

Ballantine 323: True RMS AC voltmeter from <2 Hz to >30 MHz, 0.3 uV to 300 V full scale. Real annoying recessed BNC jack on front panel. Comparable to HP 3400A. Whereas the HP 3400A uses a thermocouple, the Ballantine 323 uses the non-linearities of diodes to measure the RMS voltage. Completely different design, but comparable performance. Ballantine made several variants of this meter and the service manual is very confusing. (OM) Grade: B+

Gotta love this one. Some idiot had rotated one of the wafers of the multi-wafer switch 180 degrees. Took a while to find this error since who would have ever thought this could happen. After this was fixed, the unit was still intermittent. The fault was traced to a loose connection internal to the meter case. Who would have ever thought this could happen either.

Gotta love this one. Some idiot had rotated one of the wafers of the multi-wafer switch 180 degrees. Took a while to find this error since who would have ever thought this could happen. After this was fixed, the unit was still intermittent. The fault was traced to a loose connection internal to the meter case. Who would have ever thought this could happen either.

Ballantine 6310A: Basic 0-1.2 MHz sine wave generator, <0.1% distortion, 600/75, balanced/unbalanced, internal/external terminated, precise amplitude control. I don't know why the world needed yet another oscillator, but Ballantine seemed to think it did. I can't think of too many reasons why I would ever use this piece as it is simply boring. Unfortunately, I have never come across the service manual anywhere. (---) Grade: C

One of those mysteries of life. Although the unit basically worked, there was some strange distortion, especially on startup. At least my solution was to tie one of the unused IC pins to ground rather than leave it open like the idiots who designed the unit did.

One of those mysteries of life. Although the unit basically worked, there was some strange distortion, especially on startup. At least my solution was to tie one of the unused IC pins to ground rather than leave it open like the idiots who designed the unit did.

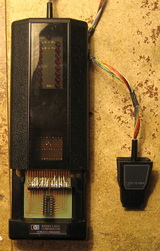

BBC M2050: Digital Scope Multimeter. A (very) poor man's version of the Fluke Scopemeter. It is a scope. It is a meter. It is a very limited scope. It is a very limited meter. For instance, the scope time base only goes down to 0.025 msec/div and the multimeter resistance tops out at 20K. Has the ability to scroll the scope up to 60 minutes and also has two memories and the ability to zoom through them. AC and DC coupling, different triggering options. Seems accurate from about 10 to 40 kHz. Not quite sure what they were thinking. But you have to admit, it is cute. And at seven bucks, how could I resist? (---) Grade: B

The four NiCd C-cells were still inside and for once they weren't leaking. Put regular alkaline batteries in, despite the warning label, because I don't have the charger. I don't know what kind of charger to use anyway seeing as I can find out absolutely nothing about this unit.

The four NiCd C-cells were still inside and for once they weren't leaking. Put regular alkaline batteries in, despite the warning label, because I don't have the charger. I don't know what kind of charger to use anyway seeing as I can find out absolutely nothing about this unit.

Beco 815-AF: Universal bridge similar to the early GenRad units, except GenRad knew how to spell the word "impedance," not "impedence." Good up to 1000 uF and will null at a resolution of about 0.1 pF on the lowest scale. One of two units. Fixed one, used the other for parts. Rumor has it that the Military needed impedance bridges and BECO managed to get around some patent infringements. Like all manually controlled bridges, it helps to know approximately what the answer is before you start. But the thing does do what it is supposed to. Has a very funky AC adapter that clips onto the side panel. BECO really intended it to be run on batteries. (---) Grade: C-

No repair really required on the first unit. It just needed some adjustments so that the oscillator would start. The second unit is faulty and the fault was traced to a shorted transformer. Most likely some previous owner had dumped a lot of volts through the external oscillator input. Seeing as I have no schematic, I don't know what to replace the transformer with. Besides, it's not worth spending the money.

No repair really required on the first unit. It just needed some adjustments so that the oscillator would start. The second unit is faulty and the fault was traced to a shorted transformer. Most likely some previous owner had dumped a lot of volts through the external oscillator input. Seeing as I have no schematic, I don't know what to replace the transformer with. Besides, it's not worth spending the money.

Biddle Gray: Basic decade resistor boxes, 1 ohm to ~111,000 ohms on the lower unit and 10K to ~11.1 Meg on the upper. About 0.035% accuracy as far as I can tell. Built like a tank with precision hand adjusted wire-wound resistors (except on the 1M range). They don't make them like they used to I guess. I actually have no idea when these were made - my guess is around 1960 (if not earlier). These are extremely handy when calibrating DMMs. (---) Grade: A-

The lower unit was fine. The upper unit, purchased about two years later, had one blown 1 Meg resistor. The resistor was marked 0.03% but I replaced it with a 0.05%, 10 ppm/degC temperature coefficient resistor for a couple of bucks. It actually measured 1.0003 Mohms on a calibrated HP 34401A DMM at work, so I guess I was lucky. I can go for the 0.02%, 5 ppm/degC Caddock resistor if I want to spend more than I paid for the whole unit. Maybe someday.

The lower unit was fine. The upper unit, purchased about two years later, had one blown 1 Meg resistor. The resistor was marked 0.03% but I replaced it with a 0.05%, 10 ppm/degC temperature coefficient resistor for a couple of bucks. It actually measured 1.0003 Mohms on a calibrated HP 34401A DMM at work, so I guess I was lucky. I can go for the 0.02%, 5 ppm/degC Caddock resistor if I want to spend more than I paid for the whole unit. Maybe someday.

Biomation 1015: Biomation (also known as Gould) produced some specialty equipment decades ago, most notably some of the first logic analyzers. This entry is one of their waveform digitizer/recorders. It basically samples 4 channels at up to 100 kHz with a total storage capacity of 4096 10-bit samples. Once a capture is made, output jacks on the back can be routed to, for instance, a scope for playback. The scope presentation is a bit unsettling at first, especially at low sample rates, because the analog waveform holds the voltage level constant until the next sample point; so the waveforms look like staircases. Looking at the picture, the left third controls the four input levels and has nifty LEDs to tell you whether you are underflowing and/or overflowing the range. The middle third controls the triggering and time base and the right third controls the mode and several types of analog and digital output selections. Built in 1975 with very good build quality and a massive 100,000 uF electrolytic capacitor on the 5V supply. With 74 front panel controls, this piece has the potential for having the all time highest button-to-dollar ratio. But only if the purchase price (not counting shipping) was low. Is $1.00 low enough? I thought so. (OM) Grade: B+

It all seems to work, but I did remove the flickering power-on light bulb, file the crap off the contact, and reinstall. I also discovered that the manual trigger LED would never come on despite the fact that the manual trigger function worked fine. I went through the tedious procedure of removing the front panel and the board behind it and quickly saw the problem. The LED was on a small daughterboard mounted perpendicularly to the main display board. But instead of using an edge connector, Biomation simply drilled a slot through the mother board and stuck the edge of the daughterboard through the slot. Solder was then used to bridge the connections between the two boards. Over time, the stresses cracked all of the solder and the daughterboard was not making contact. I would still like to calibrate the unit, but the cal procedure requires the use of two Biomation support cards which are unobtainable, so I am out of luck.

Postscript: Another few years and another malfunctioning LED. Same bad solder joints on one of the daughterboards as previously described.

It all seems to work, but I did remove the flickering power-on light bulb, file the crap off the contact, and reinstall. I also discovered that the manual trigger LED would never come on despite the fact that the manual trigger function worked fine. I went through the tedious procedure of removing the front panel and the board behind it and quickly saw the problem. The LED was on a small daughterboard mounted perpendicularly to the main display board. But instead of using an edge connector, Biomation simply drilled a slot through the mother board and stuck the edge of the daughterboard through the slot. Solder was then used to bridge the connections between the two boards. Over time, the stresses cracked all of the solder and the daughterboard was not making contact. I would still like to calibrate the unit, but the cal procedure requires the use of two Biomation support cards which are unobtainable, so I am out of luck.

Postscript: Another few years and another malfunctioning LED. Same bad solder joints on one of the daughterboards as previously described.

BK Precision 510: Attach the transistor and move the switch at the right until the NPN or PNP LED is lit. No light = bad transistor. This little innocuous piece is probably one of the most useful things I own. It has diagnosed problems countless of times. The best thing about it is that it will do in-circuit tests (as long as shunt resistances are high enough). I also have the accompanying 3-prong probe in case I don't want to use three separate clip leads. (OM) Grade: A-

Postscript: Many years later, picked up a second one of these for $18. It came with a case and three color-coded banana-to-minigrabber leads (to complement my 3-prong probe) which are really all I wanted.

The second 510 unit's eBay photo showed a severely corroded battery holder, so I knew I was going to need one of these. But it isn't a regular 4xAA holder since the 510 uses a split supply (-3V, +3V) with an extra lead coming off the holder to ground. There is no good way to add the ground lead to the place where batteries #2 and #3 meet since they use the kind of steel that is unsolderable. So the simple solution was to get two 2xAA holders and configure them for a split supply. While I was waiting for this second 510 to arrive, I verified the battery holder configuration on my first unit. And in the process of looking, that battery holder's wires crumbled into dust. So I ordered four of the 2xAA holders, enough to fix both units. The first unit was easily fixed, but the new arrival still had problems after I installed the new battery holder. One problem was an improperly soldered IC on the main board and a malfunctioning Off-Lo-Hi slide switch. I think I have both problems fixed now.

Postscript: Many years later, picked up a second one of these for $18. It came with a case and three color-coded banana-to-minigrabber leads (to complement my 3-prong probe) which are really all I wanted.

The second 510 unit's eBay photo showed a severely corroded battery holder, so I knew I was going to need one of these. But it isn't a regular 4xAA holder since the 510 uses a split supply (-3V, +3V) with an extra lead coming off the holder to ground. There is no good way to add the ground lead to the place where batteries #2 and #3 meet since they use the kind of steel that is unsolderable. So the simple solution was to get two 2xAA holders and configure them for a split supply. While I was waiting for this second 510 to arrive, I verified the battery holder configuration on my first unit. And in the process of looking, that battery holder's wires crumbled into dust. So I ordered four of the 2xAA holders, enough to fix both units. The first unit was easily fixed, but the new arrival still had problems after I installed the new battery holder. One problem was an improperly soldered IC on the main board and a malfunctioning Off-Lo-Hi slide switch. I think I have both problems fixed now.

BK Precision 520B: Transistor tester, the upgrade to the BK Precision 510 (described above). The 520B has a couple of differences: 1) it is AC powered so there are no pesky batteries to leak all over the insides; 2) it has a leakage meter; 3) it can identify Ge vs Si transistors; and 4) produces an audible tone when a good transistor is tested. It is also about 10 times the size of the 510. Some would call these 520B features actually disadvantages, particularly the audible tone - it is simply annoying. However, the tone probably has some value if one was using the 3-prong probe (see the 510 entry) and rapidly testing many transistors on a board where you wouldn't have to look up and see the red LED turn on. Of course, one can test transistors in almost all cases with a modern DMM set to diode mode. But I like these self-contained BK Precision testers. The 520B was an OK buy at $20 and arrived in mint condition. (PDF) Grade: B+

Postscript: Playing around with the 520B, I noticed that even on the LO test setting, most bipolar transistors will test OK in two lead configuration switch settings. As explained in the manual, this is due to the small gain seen in the reverse E-C direction in modern transistors. The 510, on the other hand, rarely tests OK in two switch positions on the LO setting. I think this discrepancy is due to the +/-5 volts used in the AC powered 520B versus the +/-3 volts used in the battery powered 510. It's somewhat annoying with the 520B because when two switch settings test OK, there is confusion between which is C and which is E which makes lead identification impossible.

The only thing I needed to do was to calibrate the current meter. However, if you notice, the BK 520B lead identification windows (middle right) shows E B C in terms of three colors (yellow, blue, green). These colors correspond to the colored jacks (lower right) which are also numbered one, two and three. But slide over to the transistor socket (middle bottom) where only the three numbers are shown. So if your memory isn't good, you have to constantly look at the numbers on the socket, then look at the jacks to see the corresponding colors, and then you can "read" the lead identification windows. On the BK Precision 510, they put colored dots next to the transistor socket. Why they didn't do the same on the 520B is beyond me, so I put my own colored dots on. Also, I put a switch (top right) to turn on/off that pesky audible output. That's the way the 520B should have been built in the first place.

Postscript: Playing around with the 520B, I noticed that even on the LO test setting, most bipolar transistors will test OK in two lead configuration switch settings. As explained in the manual, this is due to the small gain seen in the reverse E-C direction in modern transistors. The 510, on the other hand, rarely tests OK in two switch positions on the LO setting. I think this discrepancy is due to the +/-5 volts used in the AC powered 520B versus the +/-3 volts used in the battery powered 510. It's somewhat annoying with the 520B because when two switch settings test OK, there is confusion between which is C and which is E which makes lead identification impossible.

The only thing I needed to do was to calibrate the current meter. However, if you notice, the BK 520B lead identification windows (middle right) shows E B C in terms of three colors (yellow, blue, green). These colors correspond to the colored jacks (lower right) which are also numbered one, two and three. But slide over to the transistor socket (middle bottom) where only the three numbers are shown. So if your memory isn't good, you have to constantly look at the numbers on the socket, then look at the jacks to see the corresponding colors, and then you can "read" the lead identification windows. On the BK Precision 510, they put colored dots next to the transistor socket. Why they didn't do the same on the 520B is beyond me, so I put my own colored dots on. Also, I put a switch (top right) to turn on/off that pesky audible output. That's the way the 520B should have been built in the first place.

BK Precision 801: Capacitance tester for the 1960's TV repairman. Has an actual vacuum tube inside. Works very well for moderate values of C. I have two things with vacuum tubes - this unit and the GenRad noise generator. Maybe now I need to buy a tube tester? (PDF) Grade: C

This was a simple fix. It just needed a dual pot replaced.

This was a simple fix. It just needed a dual pot replaced.

BK Precision 830: Automatic capacitor tester in 10 ranges from 199.9 pF to 199.9 mF full-scale with 0.1% best case accuracy. Not much to do except pop in a capacitor into the clips (or use the banana plugs with clip leads) and read the meter. Takes a few seconds with large capacitors to do the auto-up-ranging and I question the accuracy for small caps < 50 pF (seems to read a bit low). But it is small and portable (runs on four C-cells) and is convenient when I don't feel like using my good LCR meters across the room. Came with case, original manual and original warranty card. I wish to commend BK Precision (Dynascan) because not only is the internal construction first rate, the manual (with schematic and parts list) fully explains the design in very understandable terms. (OM) Grade: A-

There was really nothing to do except Dremel off the corrosion on the battery clips and install a new set of batteries.

Postscript: Went back and did the calibration procedure. The thing was horribly out of adjustment. The readings, especially at low values, are much more accurate now.

There was really nothing to do except Dremel off the corrosion on the battery clips and install a new set of batteries.

Postscript: Went back and did the calibration procedure. The thing was horribly out of adjustment. The readings, especially at low values, are much more accurate now.

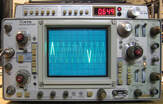

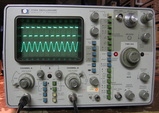

BK Precision 1570: Two (almost four) channel 70 MHz dual timebase oscilloscope. The 1570 is a re-badge of the Kenwood CS-2070 scope. Although the front panel says BK Precision, the boards inside are all marked with Kenwood part numbers. I call this scope "almost four" channels because channels #3 and #4, although usually used for external triggering, can be viewed when the scope is put in "quad" mode. These two channels, however, have a fixed volts/div scale of 0.1 making them sort of useless for general purpose input signals. Otherwise, the scope does what it is supposed to do with minimal fuss. This would be an almost perfect scope if it had automatic peak-to-peak triggering like most of the Tektronix scopes. The design is typical of high end consumer grade electronics (see BK Precision Bonus Rant immediately following) and consists of only two custom designed pre-amp chips. There are a few 7400 and 4000 series logic chips used mainly to service the various front panel selections; the rest of the scope is implemented basically with discrete transistors. A high-end scope manufacturer like HP, Tektronix or Phillips would have designed a few custom triggering and sweep ICs and been done with it. Oh, there are also north of 50 adjustment pots and caps in this beast and there is no cooling fan despite the scope drawing about 65 watts. (PDF) Grade: B

There were several different eBay auctions offering the 1570 at prices less than $75. I chose mine because the listing photo at least showed traces on the screen (I paid $40). When received, the scope was pretty filthy and a lot of it didn't work. The faults were all mechanical, not electrical, and involved a lot of contact cleaner and some touch up soldering. However, there was one big problem. For some idiotic reason, the vertical position adjustments for channel #3 and #4 have their knobs on the side of the cabinet. The pots are on an internal board and the knobs simply come out through two holes cut in the cabinet. There is a warning on the back panel instructing you to remove these two knobs before sliding the cabinet off. The previous owner didn't heed that warning and cracked both pots in half. I managed to remove the pots, put them back together and re-install. A couple of days later, something wasn't working right so I pulled the cabinet off again to take a look. I guess I am the idiot because I yanked the cabinet off without first removing the two knobs. Cracked the pots again and I had to do the repair all over. The calibration went OK as far as I could do it. The timebase board was an earlier version than what is described in the CS-2070 manual and hence none of the adjustments matched. Trial and error has me pretty close, but there is a small error in the timebase that I will have to live with.

Postscript: When I first got the 1570, the channel selection function was not operating properly, but promptly fixed itself. Unfortunately, the fault reared up again and seems to occur only when the unit is cold. There are a bunch of OR gates (74LS32) feeding a J-K flip flop with master set and reset (74LS112), and the reset pin of the 74LS112 (when supposed to be low) was 1.5V - sort of indeterminate for TTL logic. I replaced the 74LS112, but that was not the problem. The 74LS32 output, which drives the 74LS112 through a diode (reverse) was only pulling down to about 0.8V (hence the 1.5V on the 74LS112 was one diode drop higher). But the big clue was when I put my thumb on the 74LS32 and pressed firmly. Down it went from 0.8V to about 0.15V. I removed and resoldered the 74LS32 and all seems OK now - no more changes with my thumb.

Postscript^2: Would really help if I soldered the 74LS112 properly and a wire didn't fall off the channel #3 vertical position pot. NOW everything works properly!

Postscript^3: Well, everything worked for a few weeks. Then same old problem with the channel selection. This time I pulled out the 74LS112 and took a bunch of traces with it. I point-to-point rewired all the missing traces and found a couple of marginal solder joints on a few other adjacent chips. Hopefully this fixes the damn thing once and for all.

BK Precision Bonus Rant: This is more of an observation than a rant. In my opinion, when looking at electronic equipment manufactured before, say, the year 2000, one can put them in one of three categories. The first category is low-grade consumer electronics like what would be found in a cheap AM/FM clock radio. These have the lowest quality boards and components and are clearly designed to be as cheap as possible. The third category is high-end test equipment like what would be found in a typical HP or Tektronix piece. Highest quality everything and clearly designed with less (or no) emphasis on cost. The second, middle category is what I will call high-end consumer grade. If you've ever worked on a ham radio transceiver from Icom, Yaesu or Kenwood, those are good examples. The components tend to be high quality, the boards less so, and almost every function is put on some PC board with the result that there are dozens and dozens of little connectors everywhere because none of the boards plug into any kind of main motherboard. The BK 1570 scope is a prime example of this second category. However, in the case of the 1570, I have never seen ANY piece of electronics with as many add-ons, bodges and revisions. For instance, the vertical preamplifier board must have at least 25 resistors, diodes, capacitors, etc. tacked on to the original board. The horizontal timing board has a little circuit board that was added by hot gluing it on standoffs to the timing board and the underside of the board is a nightmare of tacked-on circuitry. All in all, someone at BK Precision must have spent hours and hours making all the mods.

There were several different eBay auctions offering the 1570 at prices less than $75. I chose mine because the listing photo at least showed traces on the screen (I paid $40). When received, the scope was pretty filthy and a lot of it didn't work. The faults were all mechanical, not electrical, and involved a lot of contact cleaner and some touch up soldering. However, there was one big problem. For some idiotic reason, the vertical position adjustments for channel #3 and #4 have their knobs on the side of the cabinet. The pots are on an internal board and the knobs simply come out through two holes cut in the cabinet. There is a warning on the back panel instructing you to remove these two knobs before sliding the cabinet off. The previous owner didn't heed that warning and cracked both pots in half. I managed to remove the pots, put them back together and re-install. A couple of days later, something wasn't working right so I pulled the cabinet off again to take a look. I guess I am the idiot because I yanked the cabinet off without first removing the two knobs. Cracked the pots again and I had to do the repair all over. The calibration went OK as far as I could do it. The timebase board was an earlier version than what is described in the CS-2070 manual and hence none of the adjustments matched. Trial and error has me pretty close, but there is a small error in the timebase that I will have to live with.

Postscript: When I first got the 1570, the channel selection function was not operating properly, but promptly fixed itself. Unfortunately, the fault reared up again and seems to occur only when the unit is cold. There are a bunch of OR gates (74LS32) feeding a J-K flip flop with master set and reset (74LS112), and the reset pin of the 74LS112 (when supposed to be low) was 1.5V - sort of indeterminate for TTL logic. I replaced the 74LS112, but that was not the problem. The 74LS32 output, which drives the 74LS112 through a diode (reverse) was only pulling down to about 0.8V (hence the 1.5V on the 74LS112 was one diode drop higher). But the big clue was when I put my thumb on the 74LS32 and pressed firmly. Down it went from 0.8V to about 0.15V. I removed and resoldered the 74LS32 and all seems OK now - no more changes with my thumb.

Postscript^2: Would really help if I soldered the 74LS112 properly and a wire didn't fall off the channel #3 vertical position pot. NOW everything works properly!

Postscript^3: Well, everything worked for a few weeks. Then same old problem with the channel selection. This time I pulled out the 74LS112 and took a bunch of traces with it. I point-to-point rewired all the missing traces and found a couple of marginal solder joints on a few other adjacent chips. Hopefully this fixes the damn thing once and for all.

BK Precision Bonus Rant: This is more of an observation than a rant. In my opinion, when looking at electronic equipment manufactured before, say, the year 2000, one can put them in one of three categories. The first category is low-grade consumer electronics like what would be found in a cheap AM/FM clock radio. These have the lowest quality boards and components and are clearly designed to be as cheap as possible. The third category is high-end test equipment like what would be found in a typical HP or Tektronix piece. Highest quality everything and clearly designed with less (or no) emphasis on cost. The second, middle category is what I will call high-end consumer grade. If you've ever worked on a ham radio transceiver from Icom, Yaesu or Kenwood, those are good examples. The components tend to be high quality, the boards less so, and almost every function is put on some PC board with the result that there are dozens and dozens of little connectors everywhere because none of the boards plug into any kind of main motherboard. The BK 1570 scope is a prime example of this second category. However, in the case of the 1570, I have never seen ANY piece of electronics with as many add-ons, bodges and revisions. For instance, the vertical preamplifier board must have at least 25 resistors, diodes, capacitors, etc. tacked on to the original board. The horizontal timing board has a little circuit board that was added by hot gluing it on standoffs to the timing board and the underside of the board is a nightmare of tacked-on circuitry. All in all, someone at BK Precision must have spent hours and hours making all the mods.

BK Precision 2832: This is a basic 3-1/2 digit multimeter measuring voltage, current, resistance and limited capacitance. Nowadays you can get something similar at Radio Shack for under $20. I thought I was buying one of these, but five actually showed up in various states of disrepair. It is the only thing I have that has a diode tester. And that's the only time I ever use it. Battery powered. (---) Grade: C

Most of the fixes were simple stuff like broken wires. Kept a couple and threw the rest in the garbage.

Most of the fixes were simple stuff like broken wires. Kept a couple and threw the rest in the garbage.

BK Precision 3010: 1 MHz function generator, pretty basic. Suitable for trade schools, the 3010 does sine, square and triangle waveforms, although there are provisions on the back panel for inputting a VCO voltage. The 3010 has a 600 ohm output impedance and will do 10 Vp-p into a 600 ohm load and about 25 Vp-p open circuit. The specs say <1% distortion, but I am getting about 0.5%. However, the spec also says the rise time (at the highest frequency) should be <100 nsec; I'm getting about 170 nsec. Pretty anemic, single-sided PC board (with lots of jumpers). BK Precision, or whoever actually designed and made this thing, definitely was trying to hit a price point. I bought the 3010 for $40 only because the eBay test equipment listings have been sparse lately and I was getting desperate to fix something. The catch was that my $40 got me four of these! However, it wasn't until I went to plug them in that I realized BK used a non-standard AC receptacle. That earns them a full one letter grade deduction. (PDF) Grade: C

Advertised as being bought from a local college in a surplus sale, the seller said he couldn't test it because he did not have a power cord or test leads. Well, I have heard that excuse a million times and thought nothing of it. But when I received the four units, it was clear why the seller did not have a power cord - probably nobody has a power cord. I have no idea why BK used a non-standard AC receptacle. Not even the old-style HP cord is usable. Moreover, the way that the existing receptacle is riveted into a small metal bracket makes it impossible to replace with a standard IEC socket. I'm not sure at this point what I want to do. I could drill a hole in the back and make a captive power cord. Or I could try to drill a square hole for an IEC socket in the back plastic panel. In the meantime, a couple of minigrabbers onto the pins of the AC receptacle will have to do.

When received, none of the four units worked correctly. However, a liberal dose of contact cleaner in the front panel switches and pots rendered all four functional. The 600 ohm output is not to my liking (let alone the excessive rise time), so I converted one unit to 50 ohms (now getting about 60 nsec rise time). I also added a front panel power LED. Finally, I decided to drill a hole in back and run a captive power cord.

Advertised as being bought from a local college in a surplus sale, the seller said he couldn't test it because he did not have a power cord or test leads. Well, I have heard that excuse a million times and thought nothing of it. But when I received the four units, it was clear why the seller did not have a power cord - probably nobody has a power cord. I have no idea why BK used a non-standard AC receptacle. Not even the old-style HP cord is usable. Moreover, the way that the existing receptacle is riveted into a small metal bracket makes it impossible to replace with a standard IEC socket. I'm not sure at this point what I want to do. I could drill a hole in the back and make a captive power cord. Or I could try to drill a square hole for an IEC socket in the back plastic panel. In the meantime, a couple of minigrabbers onto the pins of the AC receptacle will have to do.

When received, none of the four units worked correctly. However, a liberal dose of contact cleaner in the front panel switches and pots rendered all four functional. The 600 ohm output is not to my liking (let alone the excessive rise time), so I converted one unit to 50 ohms (now getting about 60 nsec rise time). I also added a front panel power LED. Finally, I decided to drill a hole in back and run a captive power cord.

Boonton 82AD: A weak version of the HP 8901A modulation analyzer. Pretty accurate, but running it in the "manual" mode using the level control is wishful thinking. I would put the performance of this unit midway between the HP 8901A and the Marconi TF2304. Nothing special. ($CD) Grade: B+

Someone decided that the unit might like to measure the modulation of a few hundred watt signal. Front end - poof! The input board was actually burnt to a crisp. I removed all the parts, cleaned the board up, added jumpers where the traces had vaporized, and installed new parts. I also had to replace the level potentiometer and repair a short on the GPIB board.

Postscript: See the "Remote" light on the front panel in the picture? I thought I had completely fixed the GPIB board, but the thing sporadically will come up this way (with the front panel locked out). I tested a lot of the chips on the GPIB board, but could find nothing wrong. Then it occurred to me to check the 5V rail - it was 4.5V. So no wonder the GPIB circuitry was flaky. I didn't think at first to check the voltages because the rest of the machine had the correct 5V. But after consulting the schematic, turns out that Boonton ran a dedicated isolated supply for the GPIB board which consists of a bridge rectifier and cap providing 10V unregulated and a 5V regulator on the GPIB board itself. Turns out that the cap was bad and was only supplying about 8V to the regulator through a 5 ohm resistor. The current drawn by the GPIB board then reduced the input voltage to the regulator to about 6V - not enough. A new cap cured all ills.

Someone decided that the unit might like to measure the modulation of a few hundred watt signal. Front end - poof! The input board was actually burnt to a crisp. I removed all the parts, cleaned the board up, added jumpers where the traces had vaporized, and installed new parts. I also had to replace the level potentiometer and repair a short on the GPIB board.

Postscript: See the "Remote" light on the front panel in the picture? I thought I had completely fixed the GPIB board, but the thing sporadically will come up this way (with the front panel locked out). I tested a lot of the chips on the GPIB board, but could find nothing wrong. Then it occurred to me to check the 5V rail - it was 4.5V. So no wonder the GPIB circuitry was flaky. I didn't think at first to check the voltages because the rest of the machine had the correct 5V. But after consulting the schematic, turns out that Boonton ran a dedicated isolated supply for the GPIB board which consists of a bridge rectifier and cap providing 10V unregulated and a 5V regulator on the GPIB board itself. Turns out that the cap was bad and was only supplying about 8V to the regulator through a 5 ohm resistor. The current drawn by the GPIB board then reduced the input voltage to the regulator to about 6V - not enough. A new cap cured all ills.

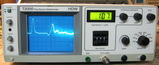

Boonton 8210: A weak version of the Boonton 82AD listed above. Responds to RF from 2 MHz to 1.5 GHz with FM deviations of up to 100 kHz and AM depths to 100%, both in 10 and 100 ranges. Pretty self-explanatory from the picture. The demodulator does its thing and a Z80A uP does its thing. (PDF) Grade: B+

Advertised as display not working, I thought it would be a simple fix. I was wrong, and the culprit seemed to be the Z80A reset circuit on power-up that was not functioning correctly, so the processor would simply hang. Many pointless hours later, I still had not gotten to the bottom of it, even though the reset circuit basically consists of a resistor and a capacitor. It might have been due to the leaking AAA batteries inside that covered part of the processor board in green crud. Anyway, I'm not inclined to pursue it further. I simply lifted the reset pin of the Z80A out of the socket and attached a small pushbutton switch on the back panel that grounds the line (while being held high by a pull-up resistor). Turn it on, press the button for a second and let go. Works fine.

Postscript: To show you all what kind of fool am I, I looked at a later version of the service manual and step 2 of the troubleshooting chart is to check the memory back-up batteries. I initially thought that the absence of batteries would simply cause the calibration constants to be lost, but the unit goes through self-cal for 30 seconds upon start-up anyway. Not so fast. The schematic shows the batteries running through a DS1210 memory controller/battery back-up chip that has the nasty habit of screwing around with the RAM chip enable line if it doesn't like what it sees. Bottom line: two new AAA batteries and the thing starts right up, without any extras like my reset switch, and once the cal was completed, subsequent power-ons omit the start-up cal procedure I've seen this kind of behavior before - see the Racal 5002 below - but what confused me with the Boonton 8210 was that the thing mostly did work with my reset switch. I guess there is some checking by the uP at startup and I was able to get past that somehow.

Postscript^2: Replaced the two AAA batteries which had leaked pretty badly in their plastic enclosure (but surprisingly measured OK) and the front panel power LED (which was very dim).

Advertised as display not working, I thought it would be a simple fix. I was wrong, and the culprit seemed to be the Z80A reset circuit on power-up that was not functioning correctly, so the processor would simply hang. Many pointless hours later, I still had not gotten to the bottom of it, even though the reset circuit basically consists of a resistor and a capacitor. It might have been due to the leaking AAA batteries inside that covered part of the processor board in green crud. Anyway, I'm not inclined to pursue it further. I simply lifted the reset pin of the Z80A out of the socket and attached a small pushbutton switch on the back panel that grounds the line (while being held high by a pull-up resistor). Turn it on, press the button for a second and let go. Works fine.

Postscript: To show you all what kind of fool am I, I looked at a later version of the service manual and step 2 of the troubleshooting chart is to check the memory back-up batteries. I initially thought that the absence of batteries would simply cause the calibration constants to be lost, but the unit goes through self-cal for 30 seconds upon start-up anyway. Not so fast. The schematic shows the batteries running through a DS1210 memory controller/battery back-up chip that has the nasty habit of screwing around with the RAM chip enable line if it doesn't like what it sees. Bottom line: two new AAA batteries and the thing starts right up, without any extras like my reset switch, and once the cal was completed, subsequent power-ons omit the start-up cal procedure I've seen this kind of behavior before - see the Racal 5002 below - but what confused me with the Boonton 8210 was that the thing mostly did work with my reset switch. I guess there is some checking by the uP at startup and I was able to get past that somehow.

Postscript^2: Replaced the two AAA batteries which had leaked pretty badly in their plastic enclosure (but surprisingly measured OK) and the front panel power LED (which was very dim).

C : C&C, Chinese No-Name, Circuit Specialists, Clarke-Hess, Cushman

C&C 150U: 150 MHz frequency counter. This is a basic, no frills two-channel counter, as vanilla as it gets. Will do frequency, period and interval or ratio between channels. Input selections include AC/DC coupling, 10:1 attenuation and a 150 kHz low-pass filter. The gate time is selectable and controls the number of digits displayed (maximum of 8). The counter is designed around a custom ASIC and it is clear that C&C had one set of firmware for multiple models because pressing the function buttons leaves a "no-op" condition between Freq B and Period A where there must have been a "C" channel function in another model. Being a 7-digit per second counter, it is a good two or three orders of magnitude worse than your "normal" counter. Designed (and perhaps manufactured) in Korea, the build quality is surprisingly good. That is, until you try and fix it - then you get the real surprise (see the repair notes below). (PDF) Grade: C-